STARTER SPRAY FOAM RIG PACKAGES

OPEN & CLOSED CELL SPRAY FOAM SPECIAL PRICING

INSULATED SPRAY FOAM RIG SPECIAL PRICING

CONCRETE LIFTING & LEVELING RIG PACKAGES

ROOF COATINGS & ROOF COATING SYSTEMS

SPRAY FOAM INSULATION RIG FAQ

HOW MUCH DOES A SPRAY FOAM RIG COST?

The average cost for a spray foam rig can range between $33,000-$58,000 for starter packages and up to $93,000 for a larger capacity trailers with high-end spray foam machines designed for experienced professionals.

WILL I NEED ANY OTHER EQUIPMENT OR ACCESSORIES TO RUN MY RIG?

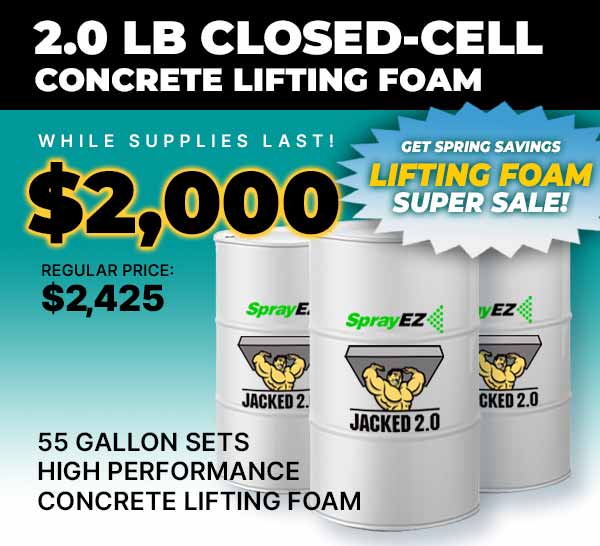

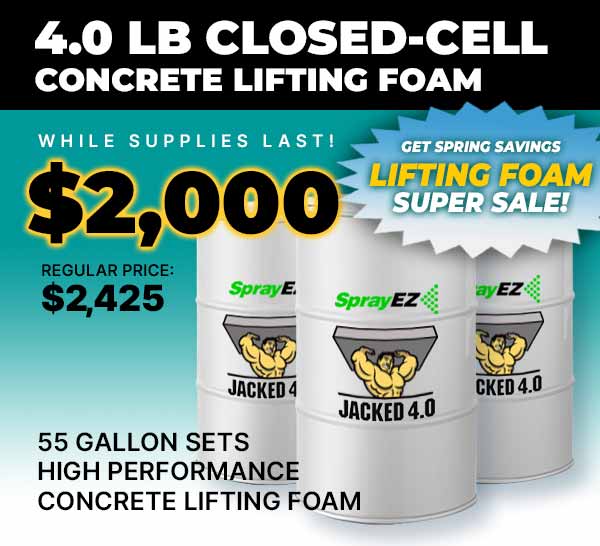

Yes. You will need to purchase spray foam (55 gallon drum sets), safety gear (PPE), thermal gun, drum mixer, solvents, release agents and cleaners to keep your equipment in top condition. You may want to purchase an extra gun to avoid down time and/or delays in completing a spray foam installation.

WHAT SIZE TRAILERS ARE USED TO BUILD A SPRAY FOAM RIG?

Trailer sizes vary and depend on the needs of your business. For those getting into the spray foam business our starter rigs are typically 7' x 16'. For more experienced operators that need more capacity we have packages that include 7' x 18', 8.5' x 20 and 8.5' x 28' Gooseneck models.

CAN I SPRAY OTHER MATERIAL WITH MY SPRAY FOAM RIG?

Your spray foam machine may be capable of spraying different types of foam and polyurea. Certain types of foam and polyurea require high pressure systems and will not mix, spray or perform properly with a low pressure system. Always consult with your sales agent and manufacturer technical data sheet for your specific system to be sure.

HOW CAN I USE MY SPRAY FOAM RIG TO OFFER CONCRETE LIFTING SERVICES?

It's easy. All you need to do is add a concrete injection gun to your spray foam rig package. See how our concrete lifting packages can help you quickly expand your business with new services. Always consult with your sales agent and manufacturer technical data sheet for your specific system to be sure.

ARE THERE WAYS TO FINANCE A SPRAY FOAM RIG?

Yes! Spray Equipment & Coatings has a lending partner that specializes in equipment loans. The application takes just minutes and you'll know how much you qualify for in hours. APPLY NOW!

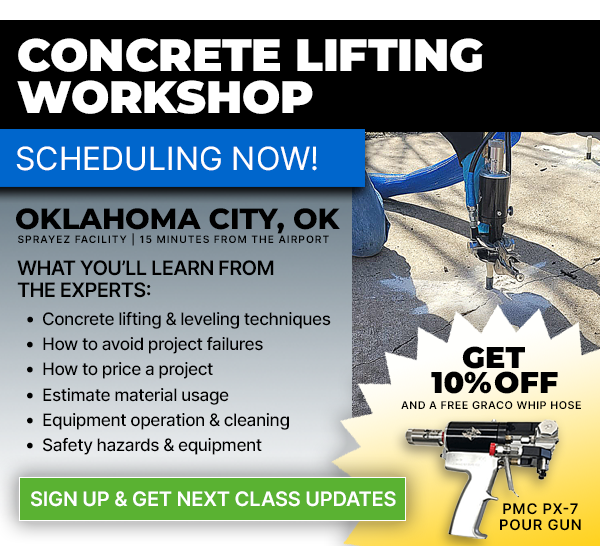

WILL I NEED TO TAKE A CLASS OR BE TRAINED HOW TO USE THE SRAY FOAM EQUIPMENT?

When your spray rig is delivered or when it is picked up at one of our facilities we will teach you and your team how the system and equipment operates. You will learn the best practices in maintaining the machine and components of the system, how to apply foam properly and apply it in a safe manner. These training sessions usually last a day.

HOW MUCH MAINTENANCE DOES SPRAY FOAM EQUIPMENT REQUIRE?

Like any other mechanical devices, spray machines and the other components require periodic maintenance to run properly. During your training session you will learn about the intervals in which to check your system and perform these duties. Some of the system components you will be familiar with and require basic care.

Spray foam machines handle chemical compounds that need to be recirculated if the time between usage is greater than a few days. For longer intervals of time between use, you will need to flush the lines and clear the spray gun. Your trainer will walk you through these processes to ensure optimal performance.

ARE THERE ANY SAFETY CONCERNS OR HEALTH RISKS WHEN SPRAYING FOAM?

Yes. You will need to wear protective eyewear, full-face respirators, full-coverage clothing and ventilate the area being sprayed. In a closed environment this gear is an absolute necessity. If the ventilation of the area being sprayed is inadequate a fresh air system or supply may be needed.

WHAT IS THE DIFFERENCE BETWEEN CLOSED AND OPEN CELL SPRAY FOAM?

The difference between closed and open cell foam comes down to their physical propteries and cell structure. Each type has an application where it performs best and both share good insulation R-Value, structure sealing and sound dampening qualities.

Open cell is lighter in weight, lower in density, less rigid and has a higher expansion rate. Most open cell applications are for dry areas that are not exposed to extreme moisture or water.

Closed cell in comparison is heavier in weight, more dense, rigid and adds structural integrity, has lower expansion rate and is waterproof. Closed cell foam is ideal for areas that may be exposed to extreme moisture, direct exposure to water.

HOW MANY BOARD FEET DOES A 55 GALLON DRUM OF SPRAY FOAM COVER?

The average yield of closed cell spray foam ranges from 4,300 - 4,500 sqft at 1" of depth. Open cell foam coverage ranges from 17,000 - 20,000 sqft at 1" of depth. Actual yield results will vary and depend on how evenly the foam is applied and environmental conditions at the time it was sprayed. Use our spray foam set calculator to estimate how much foam you need to order for your next project.

HOW DO I CALCULATE HOW MANY SETS OF SPRAY FOAM I NEED FOR MY PROJECT?

You will need to estimate the volume of spray foam needed to complete your project. Measure the overall wall dimensions that will be sprayed, LENGTH x HEIGHT then subtract the area of the door and window openings. To calculate the volume of foam needed for 2" x 4" walls multiply by 3.5, for 2" x 6" walls multiply by 5.5. To determine the number of foam sets need to complete your project divide the VOLUME total by the average YIELD value for the foam you will be spraying. This calculation will result in the number of sets needed. Remeber to round up to the next WHOLE NUMBER, drum sets are whole units and can't be broken in to smaller sizes.

Use our spray foam set calculator to estimate how much foam you need to order for your next project.

BUILD A CUSTOM SPRAY RIG

BUILT TO YOUR SPECIFICATIONS

Fill out our easy-to-use form and select your trailer size & configuration, machine type, hose length, electric and lighting requirements, power supply and air compressor. When you send it to us, we’ll go over the details of your build with you, answer any questions or concerns you may have and prepare an estimate. With your approval and financing secured we’ll proceed with the assembly of your rig. Our current assembly time is approximately 4-6 weeks.

Equipment training will be provided. Rig financing options are available.